Antioxidant 168 CAS Number: 31570-04-4

| Product | Antioxidant 168 |

| CAS | 31570-04-4 |

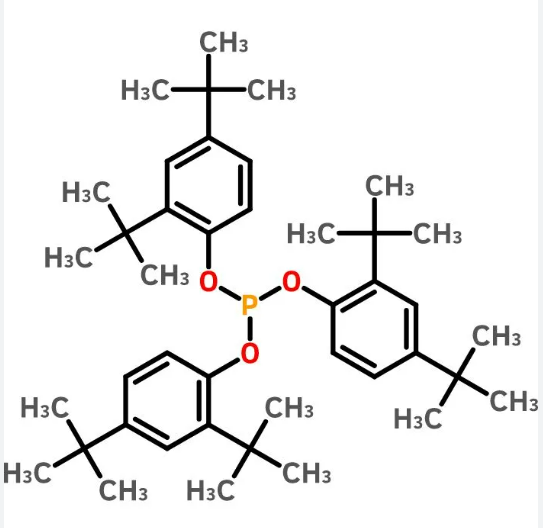

| MF | C42H63O3P |

| Formula | Phenol,2,4-bis(1,1-dimethylethyl,phosphite(3:1);tri(2,4-Ditertrabutylphenyl)phosphiteester;Tris(2,4-di-tert-butylphenyl)phoshit;Doverphos-S-480;PhosphorousacidChemicalbooktri(2,4-di-tert-butylphenyl)ester;

Phosphorousacidtris[2,4-bis(tert-butyl)phenyl]ester;Tris(2,4-di-tert-butylphenyloxy)phosphine;4-di-tert-butylphenyl)phosphite |

product description

Basic Info.

Antioxidant 168 Properties

| Melting point | 181-184 °C(lit.) |

|---|---|

| Boiling point | 594.2±50.0 °C(Predicted) |

| Density | -0.98 |

| Flash point | 46°C (115°F) |

| storage temp. | 2-8°C |

| solubility | Acetonitrile (Slightly), Chloroform (Sparingly), Ethyl Acetate (Sparingly, Heate |

| form | Powder |

| color | white |

| Specific Gravity | 0.98 |

| Hydrolytic Sensitivity | 4: no reaction with water under neutral conditions |

| Sensitive | moisture sensitive |

| Stability | Moisture Sensitive |

| InChIKey | JKIJEFPNVSHHEI-UHFFFAOYSA-N |

| SMILES | CC(C)(C)c1ccc(OP(Oc2ccc(cc2C(C)(C)C)C(C)(C)C)Oc3ccc(cc3C(C)(C)C)C(C)(C)C)c(c1)C(C)(C)C |

| LogP | 18 at 25℃ |

| Indirect Additives used in Food Contact Substances | TRIS(2,4-DI-TERT-BUTYLPHENYL) PHOSPHITE |

| FDA 21 CFR | 178.3570 |

| CAS DataBase Reference | 31570-04-4(CAS DataBase Reference) |

| FDA UNII | 834E5H0LFF |

| EPA Substance Registry System | Tris(2,4-di-tert-butylphenyl) phosphite (31570-04-4) |

| UNSPSC Code | 41116107 |

| NACRES | NA.24 |

SAFETY

Risk and Safety Statements

| Symbol(GHS) |  GHS07 |

|---|---|

| Signal word | Warning |

| Hazard statements | H315-H319 |

| Precautionary statements | P264-P280-P302+P352+P332+P313+P362+P364-P305+P351+P338+P337+P313 |

| PPE | Eyeshields, Gloves, type N95 (US) |

| WGK Germany | – |

| TSCA | TSCA listed |

| HS Code | 2920900002 |

| Storage Class | 13 – Non Combustible Solids |

Antioxidant 168 Chemical Properties,Uses,Production

Characterization

Antioxidant 168 is a hydrolytically stable phosphite processing stabilizer. As a secondary antioxidant,Antioxidant 168 reacts during processing with hydroperoxides formed by autoxidation of polymers preventing process induced degradation and extending the performance of primary antioxidants.

Reactions

- Precursor to a palladacyclic catalyst for Suzuki, Stille and Heck processes.

- Ligand for Pd-catalyzed [3+2] intramolecular cycloaddition of alk-5-enylidenecyclopropanes.

- Ligand for Pt-catalyzed intramolecular silaboration of alkenes.

- Ligand for Ni-catalyzed aminocarbonylation of aryl halides.

- Ligand for the Au-catalyzed [4+2] intramolecular cycloaddition of allene-dienes.

- Rhodium-Catalyzed Allylic Substitution with an Acyl Anion Equivalent.

Applications

The application range of Antioxidant 168 -synergistically combined with other Ciba anti-oxidants – comprises polyolefins and olefin-copolymers such as polyethylene (e.g. HDPE, LLDPE), polypropylene, polybutene and ethylene-vinylacetate copolymers as well as polycarbonates and polyamides. The blends can also be used in polyesters, styrene homo- and copolymers, adhesives and natural and synthetic tackifier resins, elastomers such as BR, SEBS, SBS, and other organic substrates. Antioxidant 168 blends can be used in combination with light stabilizers of the TINUVIN and CHIMASSORB range.

Features/benefits

Antioxidant 168 is an organophosphite of low volatility and is particularly resistant to hydrolysis. It

protects polymers which are prone to oxidation, during the processing steps (compounding/

pelletizing, fabrication and recycling) from molecular weight change (e.g. chain scission/crosslinking)

and prevents discoloration.

Antioxidant 168 performs best when combined with other Ciba antioxidants. Blends of Antioxidant 168

with antioxidants of the IRGANOX range (IRGANOX B-blends) and with Hydroxylamine FS042 are

particularly effective. The IRGANOX range antioxidants additionally provide storage stability and give

the polymer long term protection against thermo-oxidative degradation.

Antioxidant 168 comprised in phenol free systems with other appropriate Ciba stabilizers addresses

specific stabilization requirements.

Guidelines for use

Typically 500 – 2000 ppm of Antioxidant 168 combined with appropriate levels of other additives are used for the processing stabilization of polymers. The optimum level is application specific. Extensive performance data of Antioxidant 168 combinations in various organic polymers and applications are available upon request.

Physical Properties

Safety

In accordance with good industrial practice, handle with care and prevent contamination of the

environment. Avoid dust formation and ignition sources.

For more detailed information please refer to the material safety data sheet.

Description

ANTIOXIDANT 168 is a secondary antioxidant with excellent resistance to extraction by water, low volatility and high heat stability. It can effectively decompose hydroperoxides produced during the processing of polymeric materials. ANTIOXIDANT 168 usually not used alone, is compounded with hindered phenolic primary antioxidants such as 1010 to improve thermostability of polymer during the processing. There are over ten kinds of blends of 168 with phenolic antioxidants, widely use in the polymer materials such as PE, PP, PA, PC, ABS and so on.

Uses

Tris(2,4-tert-butylphenyl) Phosphite is an intermediate in the synthesis of Tris(2,4-di-tert-butylphenyl)phosphate (T884500), a processing stabilizer for polymers.

Uses

This product is an excellent Antioxidant wnameely applied to polyethylene, polypropylene, polyoxymethylene, ABS resin, PS resin, PVC, engineering plastics, binding agent, rubber, petroleum etc. for product polymerization.

Application

Antioxidant 168 is a kind of phosphite ester antioxidant as processing stabilizer, used for polypropylene, polyethylene, and adhesives. The amount to be used may be 0.1%~1.0% depending on the substrate, processing conditions, and requirements of the end application. Blends with hindered phenols are particularly effective.In addition, they use combination with light stabilizers when need.

Definition

ChEBI: Phenol, 2,4-bis(1,1-dimethylethyl)-, phosphite (3:1) is an alkylbenzene.

General Description

Tris(2,4-di-tert-butylphenyl) phosphite is a triaryl based phosphite that can be used in catalysis and metallation. Its characteristic to undergo metallation reaction and provide a cost effective synthetic processes allows it to be useful in biaryl coupling reactions.

Flammability and Explosibility

Not classified

Safety

Antioxidant 168 is approved for indirect food contact applications.

Synthesis

96-76-4

31570-04-4

(1) First, 11.0 g of 2,4-di-tert-butylphenol was added to a 250 mL three-neck flask. Subsequently, 22 mg of diatomaceous earth-loaded pyridine catalyst and 400 mL of a solvent mixture of methanol and toluene (1:1 by volume) were added. A magnetic stirrer, reflux condenser tube were installed and a thermometer and a dropping funnel were fixed at the remaining two ports of the three-necked flask, respectively. (2) Place the reaction apparatus in step (1) in an oil bath and programmatically warm the reaction mixture at a rate of 5 °C/10 min to 40 °C and stir the reaction mixture at this temperature. (3) A solution of 5.57 g of phosphorus trichloride dissolved in 30 mL of toluene was slowly added dropwise through a dropping funnel to the reaction system in step (2), with a controlled dropping time of 15 min. After the dropwise addition was completed, the reaction was continued to be heated to 95 °C and maintained for 30 min. Upon completion of the reaction, the solvent was removed by distillation under reduced pressure. The crude product was recrystallized with hexane to give tris(2,4-di-tert-butylphenyl) phosphite in 98.3% yield and 98.9% purity.

Properties and Applications

|

TEST ITEMS |

SPECIFICATION |

|

APPEARANCE |

WHITE INCOMPACT POWDER |

|

CONTENT |

99.0% min |

|

MELTING RANGE |

|

|

VOLATILE |

0.3% max |

|

SOLUBILITY 2g/20ml TOLUENE |

CLEAR |

|

FREE 2,4-DITERT-BUTYPHENOL |

0.2% max (wt) |

|

TRANSMITTANCE |

98% min 425nm |

|

98% min 500nm |

|

|

ACID VALUE,mg KOH/g |

0.3% max |

|

HYDROLYSIS TIME (90°C WATER ) |

14 h min |

|

SOLUBILITY |

1% ACETONE |

| 30% TOLUENE | |

| 36% CHLOROFORM | |

| 4% ETHYL ACETATE | |

| 11% n-HEXANE | |

| 0.1% ETHANOL | |

| 36% DICHLOROETHANE | |

| 6% max PHENYLETHYLENE | |

| 0.01% max WATER |

References

[1] Patent: CN108467406, 2018, A. Location in patent: Paragraph 0038-0040; 0044-0046; 0050-0052; 0056-0058; 0062

Antioxidant 168 Preparation Products And Raw materials

FAQ

Q1: About the after-sale service of products

A: After purchasing the products from our factory, we have A professional technical team and after-sales team to serve you and solve all your problems in the future.

Q2: Can I get some samples?

A: Yes, we can provide samples, but the customer will pay the freight.

Q3: How do I start paying?

Payment can be made by wire transfer or T/T, apple_pay, google_pay, gc_real_time_bank_transfer , etc.

Q4: How to confirm product quality before placing an order?

A: You can get free samples of some products. You just have to pay the shipping fee or arrange for the sample to be sent to us by express.

You can send us your product specifications and requirements and we will produce products according to your requirements.

Q5: What is your MOQ?

A: The minimum quantity we can order is 1kg.

But usually we can accept a smaller quantity, say 100g, at the cost of 100% sample charge.

Q6: Shipping Time?

A: We ship the parcel out in 1-2 days and offer tracking No.. Shipping time is different to different country. Please consult

| ACF Chemical Co., Ltd.

Leon phone/whatsapp:008615950692266 email:md@acfchemical.com No. 45 Pengwan Road, Qianwan Bonded Port Area, Qingdao Area, China (Shandong) |

|

| DMEA | 108-01-0 |

| Dodecyl trimethyl ammonium chloride | 112-00-5 |

| N-Hexadecyltrimethylammonium chloride | 112-02-7 |

| 1831 | 112-03-8 |

| 1631Br | 57-09-0 |

| D821 | 5538-94-3 |

| D8/1021 | 68424-95-3 |

| D1021 | 7173-51-5 |

| D1821 | 61789-80-8 |

| TEP88 | 157905-74-3 |

| 1227 C12 | 139-07-1 |

| DMPT(N,N-Dimethyl-p-toluidine) | 99-97-8 |

| NDPT(N,N-dihydroxyethyl-p-toluidine) | 3077-12-1. |

| DMA(N,N-dimethylaniline) | 121-69-7 |

| N,N-Diethylaniline | 91-66-7 |

| MT(M-Toluidine) | 108-44-1 |

| PT(P-Toluidine) | 106-49-0 |

| O-Toluidine OT | 95-53-4 |

| Dimethyl(octyl)amine | 7378-99-6/1120-24-7 |

| C16-18-alkyldimethyl Octadecyl/Hexadecyl dimethylamines | 68390-97-6 |

| Octadecyl/behenyl dimethylamines | 124046-42-0 |

| N,N-dimethyldocosylamine | 21542-96-1 |

| N-Methyldioctylamine | 4455-26-9 |

| Di(octyl/decyl) methylamines | 308062-61-5 |

| Didecyl methylamine | 7396-58-9 |

| N-methyldidodecylamine | 2915-90-4 |

| Dipalmitamine | 16724-61-1 |

| Trioctylamine | 1116-76-3 |

| Trioctylamine | 68814-95-9 |

| N-3-Laurylamidopropyl dimethylamine | 3179-80-4 |

| N-3-(Hydrogenated cocoamido)propyl dimethylamines | 288095-05-6 |

| N-3-Oleylamidopropyl dimethylamine | 109-28-4 |

| N-3-Erucylamidopropyl dimethylamine | 60270-33-9 |

| N-Oleyl 1,3-propanediamine | 7173-62-8 |

| Bis(aminopropyl)laurylamine | 2372-82-9 |

| N-tallow alkyltripropylenetetra | 68911-79-5 |

| 3-(isodecyloxy)propylamine | 30113-45-2 |

| N-[3-(isodecyloxy)propyl]propane-1,3-diamine | 72162-46-0 |

| 2-(Methylamino)ethanol | 109-83-1 |

| N-Methyldiethanolamine | 105-59-9 |

| 3-Methoxy propyl amine | 5332-73-0 |

| N,N-dimethylcyclohexylamine | 98-94-2 |

| 1,3,5-Tris[3-(dimethylamino)propyl]hexahydro-1,3,5-triazine | 15875-13-5 |

| N,N,N’-trimethylamino-N’-ethylethanolamine | 2212-32-0 |

| N,N-Dimethylethanolamine | 108-01-1 |

| Acetone | |

| Acrylic acid | |

| Adipic acid | |

| Alpha-Methylstyrene (AMS) | |

| Benzoic Acid | |

| Bisphenol A | |

| Butyl Acrylat (BA) | |

| Butyl acetate (Butac) | |

| Butyl diglycol (BDG) | |

| Butyl glycol | |

| Para-tertiary butyl benzoic acid (PTBBA) | |

| n-Butanol | |

| n-Butyl methacrylate (n-BUMA) | |

| para-tert. Butylphenol (PTBP) | |