product description

What is Antioxidant 1010?

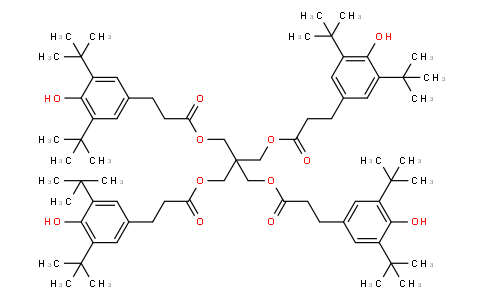

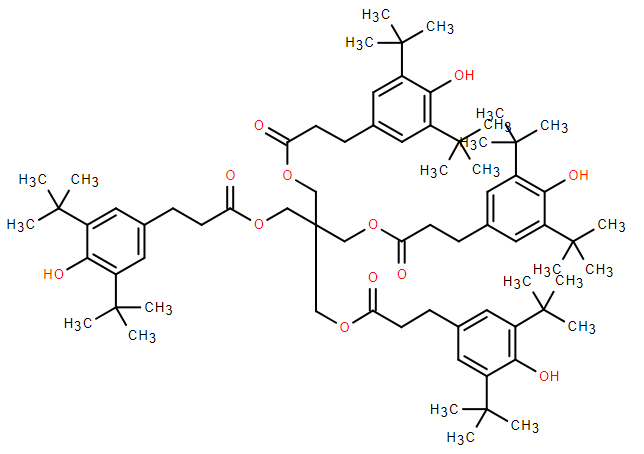

Antioxidant 1010 (Tetrakis [methylene-β-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate]methane) is a hindered phenolic primary antioxidant with high molecular weight, low volatility, and excellent thermo-oxidative stability. It is widely used in polyolefins, engineering plastics, elastomers, lubricants, and adhesives.

This product belongs to the commonly used “1010” structure in the industry and is chemically similar to the internationally widely used Irganox 1010 (BASF). It offers good compatibility and formulation interchangeability in most processing systems. Foconsci can provide different packaging specifications to facilitate transportation and use.

Irganox 1010 is usually mixed with phosphite antioxidants (Antioxidant 168) to enhance performance.

View other types of antioxidants

Structural formula:

Antioxidant 1010 Description:

| FSCI-Item | Specifications |

| CAS NO. | 6683-19-8 |

| Appearance | White powder |

| Melting point | 115.0~125.0°C |

| Loss on heating(105℃± 2℃),% | 0.50MAX |

| Ash (850℃± 25℃),% | 0.10MAX |

| Volatility,% | 0.50MAX |

| Solubleness | Limpidity |

| Transmittance 425nm

500nm |

96MIN

98MIN |

| Active component content,% | 98.0MIN |

Antioxidant 1010 Features:

Non-coloring, non-volatile, good extraction resistance:excellent product performance without the fear of side effects.

Excellent antioxidant properties: Antioxidant 1010 provides excellent protection for olefin resins such as polypropylene and polyethylene, effectively inhibiting and delaying the oxidation process of the material.

High thermal stability: AO-1010 can maintain thermal stability at processing temperatures up to 320°C, non-volatile, with long-lasting protection, ideal for high-temperature processing environments.

Environmentally friendly and non-toxic: Antioxidant 1010 is an environmentally friendly product, does not contain harmful substances and is non-toxic to the environment and human body. Mainly because of its long-lasting effect, it makes the shelf life of the material longer. It is suitable for materials in contact with food.

Synergistic effect:When used with auxiliary antioxidants such as antioxidant DLTDP and irgafos 168 produced by FSCICHEM, it can significantly improve the thermal stability and make the antioxidant effect more significant. At the same time, when used with light stabilizers, the light stability of the product can be improved.

FSCICHEM can provide total solutions for the entire plastics industry with all the products you need.

Antioxidant 1010 Uses:

1.Plastic industry:

Antioxidant 1010 is widely used in plastic products, especially in polyethylene (PE), polypropylene (PP), polystyrene (PS), ABS resin and polyurethane, to improve the heat resistance of these materials. Oxidation performance and service life.

2.Rubber industry:

Antioxidant 1010 to rubber products, such as tires and seals, can improve the heat resistance and weather resistance of the material and extend the effective service life of the product.

3.Paint and coating industry:

The application of antioxidant 1010 in paint can prevent coating aging and maintain the beauty and functionality of the coating.

Suggestion:

Antioxidant 1010 is routinely used at concentrations ranging from 0.1% to 0.5%, with specific dosage levels adjusted depending on the type of polymer and the expected process temperature and other conditions of use.

For optimal antioxidant effect, it is recommended that Antioxidant 1010 be added at the beginning of material processing.

Why Choose Foconsci As Your Antioxidant 1010 Supplier?

Top fine chemical manufacturer in China, with 15 years of experience in antioxidant 1010 production and stable production capacity.

ISO9001 quality management system certified. Ensuring consistent and reliable performance in every batch of AO-1010.

Small and bulk supply. high quality and cheap price, welcome to inquire.

Customized package: IBC containers, drums, or bulk. Can repackage into 500g or 1kg packages.

Worldwide shipping available; Spot goods

Flexible MOQ:samples supported.

Packaging:

Standard packaging: 25 kg (this chemical is packaged in cardboard barrels lined with plastic bags and three-in-one paper bags).

Bulk supply: Customized labels and specifications (OEM/ODM) are available upon request.

Storage conditions:

This product should be stored in a dry, cool, well-ventilated environment.

Avoid direct sunlight during storage and transportation, keep away from strong oxidants and acids, and pay attention to waterproofing and moisture-proofing.

When handling this product, avoid rubbing it hard to avoid damaging the packaging.

Safety Data (MSDS Highlights)

Inhalation: Use dust masks in poorly ventilated areas

Skin contact: Avoid prolonged exposure; wash thoroughly after handling

Environmental Impact: Low aquatic toxicity but not readily biodegradable

Classification: Non-hazardous under GHS regulation

Properties

| Grade | GOYENCHEM AO-1010 |

| Appearance | white solid |

| Melting point (℃) | 115 |

| Specific gravity, (20℃) | 1.15 g/ml |

| Flash point(℃) | 297 |

Solubility

(g/100g solvent, 20 °C )

| ethanol | 1.5 |

| ethylacetate | 47 |

| chloroform | 71 |

| acetone | 47 |

| methanol | 0.9 |

| methylene chloride | 63 |

| n-Hexane | 0.3 |

Features

- High effective antioxidant

- Excellent compatibility

- Prevent product deterioration during processing

- Low volatility

- Can be combined with other additives

- Versatile application

Applications

- Commodity plastic (like PVC, PE, PP, ABS, PS…)

- Engineering plastic (like PC, POM, PA…)

- Polyolefins (like polyethylene, polypropylene, polybutene)

- Olefin copolymers (like ethylene-vinylacetate copolymers)

- Polyacetals

- Polyamides

- Polyurethanes

- Synthetic rubber

- Synthetic fiber

- Elastomer

- Adhesive

- Other organic application

General Information and Properties

CAS no: 6683-19-8

Molecular formula: C25H42O3

Molecular weight: 1178 g/molPhysical Properties

Parameter Specification Appearance White, free flowing powder Melting Range 110 – 125°C Specific Gravity 0.95 to 0.99 gm/cc Viscosity @ 40°C 95 – 150 cSt Flash Point 297°C Density (20 °C) 1.15 g/ml Bulk Density 530 – 630 g/l About CAS 6683-19-8

CAS 6683-19-8 refers to the chemical identification number for Veenox Antioxidant 1010, a sterically hindered phenolic antioxidant widely used for polymer stabilization. This antioxidant, identified under CAS 6683-19-8, offers exceptional oxidative stability, making it suitable for plastics, elastomers, adhesives, and coatings. Its high molecular weight ensures low volatility and excellent processing stability, even at elevated temperatures. At Vinati Organics, we ensure that our Veenox Antioxidant 1010 (CAS 6683-19-8) meets stringent international quality standards for consistent performance in demanding applications

Properties That Influence the Application and Performance

- Oxidation Inhibition

As a primary antioxidant, CAS 6683-19-8

Antioxidant 1010 efficiently inhibits the oxidation process by scavenging free radicals, thereby preventing chain reactions that lead to material degradation. - Thermal Stability

The chemical’s impressive thermal stability allows it to function effectively in high-temperature applications, protecting materials even under elevated processing conditions. - Non-Discolouring

CAS 6683-19-8 non-discolouring nature ensures that the appearance and aesthetics of the end products remain unaffected, maintaining their visual appeal over time. - Enhanced Shelf Life

With CAS 6683-19-8, you can significantly extend the shelf life of your products, ensuring that they maintain their quality and efficacy for a longer duration. - Dosage

Dosages ranging from 500 ppm to 1000 ppm of CAS 6683-19-8 PW provide long-term thermal stability to the polymer. Higher dosages may be used depending on the substrate and the requirements of long-term thermal stability of the end application.

Applications of CAS 6683-19-8

- Polymer And Plastic Industry

CAS 6683-19-8 serves as a primary stabiliser for polymers and plastics like PVC, Masterbatch and Polyethylene, Polypropylene, Polystyrene, providing long-term protection against degradation caused by heat, light, and oxygen exposure. Its role in inhibiting chain scission and cross-linking reactions ensures the preservation of mechanical and physical properties, resulting in durable and high-quality materials. - Rubber Manufacturing

In the rubber industry, CAS 6683-19-8 contributes to the prevention of degradation, maintaining the elasticity and resilience of rubber-based products, even in challenging environments. - Adhesives and Sealants

As an antioxidant in adhesives and sealants,CAS 6683-19-8enhances the stability and performances of these formulations, promoting reliable bonding and sealing properties. - Coatings And Paints

CAS 6683-19-8 is employed as an additive in coatings and paints to protect against oxidative degradation, ensuring that coated surfaces maintain their appearance and structural integrity over time. - Lubricants And Oils

The chemical’s thermal stability makes it an ideal choice as an antioxidant for lubricants and oils, safeguarding machinery components and extending their service life. - Other Important Applications

Beyond the mentioned industries, CAS 6683-19-8 is employed in coatings, sealants, and various other applications, ensuring superior protection against degradation.

Packaging & Shipping Information

- The product is available in both PW (Powder) and GR (Granule) form.

- Packing: 25kg/Bag, 500kg/Pallet, 10MT/20’FCL.

- Our product is EU REACH certified.

As one of the leading manufacturers of organic chemical products in India, Vinati Organics takes pride in offering world-class quality antioxidant 1010. As a prominent manufacturer of CAS 6683-19-8and other cutting-edge antioxidants, vinati organics continues to make significant contributions to diverse industries worldwide.

ACF have established the effectiveness and reliability of all the chemical products through extensive research and rigorous testing, primarily to keep the process and final products organic. With an unwavering commitment to excellence and a global reputation for top-quality and highly effective products, ACF Chemical Co., Ltd. is a pioneer in manufacturing innovative chemical compounds.

Leveraging expertise in the domain, we deliver solutions that cater to your specific industrial needs. Abiding by stringent industrial standards, with ACF Chemical Co., Ltd. as your partner, thrive into the realm of excellence.

Note: For more detailed technical specifications, product data sheets, or any specific queries, please contact our customer support team.

FAQs

What physical properties does (CAS 6683-19-8) have?

Antioxidant 1010 is a white, free-flowing powder with a melting range of 110–125 °C.

It has a molecular formula of C₂₅H₄₂O₃ (for the active portion as per Vinati) and a molecular weight of around 1178 g/mol. Its flash point is very high (297 °C), which contributes to its thermal stability in high-temperature applicationsHow much Antioxidant 1010 should be used (dosage) in formulations?

The typical dosage of Antioxidant 1010(CAS 6683‑19‑8) ranges from 500 to 1,000 ppm, depending on the polymer and processing conditions. Using the correct amount ensures optimal antioxidant protection without affecting physical properties. Higher dosages may be required for long-term stability in demanding applications.

Is Antioxidant 1010 (CAS 6683-19-8) compatible with other stabilizers?

Yes it can be used in combination with secondary antioxidants such as phosphites / thioethers to create a synergistic effect. Because of its low volatility and high molecular weight, Veenox 1010 helps improve long-term performance when paired with other stabilizers. Its non-discoloring nature means it doesn’t negatively affect the aesthetic of the final product when used with other additives.

How does Antioxidant 1010 improve thermal stability in plastics?

Antioxidant 1010 (CAS 6683‑19‑8) acts as a sterically hindered phenolic antioxidant, neutralizing free radicals generated during high-temperature processing. This prevents polymer chain degradation, discoloration, and loss of mechanical properties. It is particularly effective in high-heat applications like extrusion and injection molding.

Can Antioxidant 1010 (6683‑19‑8) be used in food-contact polymers?

Yes, Antioxidant 1010 (CAS 6683‑19‑8) can be used in certain food-contact plastics such as polyethylene films and packaging materials. Its high molecular weight and low volatility minimize migration into food. Regulatory compliance should always be verified before use in food-contact applications.

Is Antioxidant 1010 compatible with other antioxidants?

Yes. Antioxidant 1010 can be blended with phosphite antioxidants, thioesters, UV absorbers, and HALS stabilizers to create synergistic stabilization packages for polymers.

- Oxidation Inhibition

| ACF Chemical Co., Ltd. Athena phone/whatsapp:008613805212761 email:ceo@acfchemical.com No. 45 Pengwan Road, Qianwan Bonded Port Area, Qingdao Area, China (Shandong) welcome to vist our factory. |

|

| Product | CAS: |

| Poly(VinylEthylEther | 25104-37-4 |

| Dodecyl methacrylate,LMA | 142-90-5、142-84-7 |

| DAIP DIALLYL ISOPHTHALATE | 1087-21-4 |

| 2-Ethylhexyl nitrate | 27247-96-7 |

| Isopropylphenyl phosphate | 68937-41-7 |

| 2-1sopropylimidazole | 36947-68-9 |

| Vinyl 2-Ethylhexanoate | 94-04-2 |

| Tolylene-2,4-diisocyanate TDI | 584-84-9 |

| Octyl-3,5-di-tert-butyl-4-hydroxy-hydrocinnamate | 125643-61-0 |

| Antioxidant 1010 | 6683-19-8 |

| Antioxidant 1076 | 2082-79-3 |

| AT-168 | 31570-04-4 |

| Nitrilotrimethylenetris(phosphonic acid)ATMP | 6419-19-8 |

| DTPMPA [[(phosphonomethyl)imino]bis[ethane-2,1- diylnitrilobis(methylene)]]tetrakisphosphonic acid |

15827-60-8 |

| PBTC 2-phosphonobutane-1,2,4-tricarboxylic acid |

37971-36-1 |

| Hydrolyzed Polymaleic Anhydride(HPMA) | 26099-09-2 |

| Methyltetrahydrophthalic andhydride(MTHPA) | 11070-44-3 |

| Methylhexahydrophthalic andhydride(MHHPA) | 25550-51-0 |

| 4-MHHPA Hexahydro-4-methylphthalic anhydride | 19438-60-9 |

| Methyl Nadic Anhydride(MNA) | 25134-21-8 |

| 3,4,5,6-THPA 3,4,5,6-Tetrahydrophthalic anhydride | 2426-02-0 |

| Toluenesulfonamide(0/PTSA) | 1333-07-9 |

| Diphenyl sulfone(DPS) | 127-63-9 |

| Propylenetetramer | 6842-15-5 |

| TBPO(tert-Butyl2-ethylhexaneperoxoate) | 3006-82-4 |

| LABSA (Linear-Alkylbenzenesulfonic Acid) | 27176-87-0 |

| EDA (Ethylenediamine) | 107-15-3 |

| Dimethyl carbonate DMC | 616-38-6 |

| MMT Methylcyclopentadienyl manganese tricarbonyl | 12108-13-3 |

| C12/18 TERTIARY AMINE(MB) | 68391-04-8 |

| Alkyl (C12-C14) Glycidyl Ether (AGE) | 68609-97-2 |

| NMA(N-methylaniline) | 100-61-8 |

| N-ethylaniline | 103-69-5 |

| C12-14-alkyldimethylamines | 84649-84-3 |

| 1-Propene, 2-methyl-, homopolymer, hydroformylation products , reaction products with ammonia | 337367-30-3 |

| PEG-40 Castor Oil (Castor oil 40 EO, Castor oil ethoxylated 40 EO) | 61791-12-6 |

| Hydrogenated PEG-40 Castor Oil (Hydrogenated castor oil 40 EO, hydrogenated castor oil ethoxylate 40 EO) – CAS 61788-85-0 | 61788-85-0 |

| Ethoxylated cocoamine EO 2 (PEG-2 cocoamine) – CAS 61791-14-8 | 61791-14-8 |

| Hydrogenated Tallow Amine ethoxylate EO 8 (PEG-8 Hydrogenated Tallow Amine) – CAS: 61791-26-2 | 61791-26-2 |

| Phenyl Glycidyl Ether | 122-60-1 |

| Neopentane Glycol Diglycidyl Ether | 17557-23-2 |

Packing

20 kg/bag